About Us

Nakshatra Process Control Industries

Nakshatra prides itself on its innovation and technical developments bringing refiner products to market which produces pulp resulting in better efficiency of paper producing industries.

Nakshatra has been progressively successful in launching new techniques working on ULTRA BOND TECHNOLOGY which consists of fixed peculiar metallurgical steel ribs at the base sector of plate connected using diffusion bonding process. The process Diffusion of metals takes place at yield temperature which gives rise to firm grip of product.

Design Factors:

- Special metallurgical steel ribs cut by 3D laser cutting and with heat treatment are inserted in the laser cut SS 17 4 PH sector plate slots and are joined by diffusion bond technology. Diffusion takes place at yield temperature to give homogenous structure.

- The narrow but high ribs cut from special metallurgical steel form a uniform gap with zero drift angle allows uniform maximum stock flow and longer retention time for development of fiber. • Weight of the tackles being lighter, it is very easy to handle while removal or fitting.

- Uniform low intensity refining with best fiber development at considerable reduction in power.

WHY NAKSHATRA

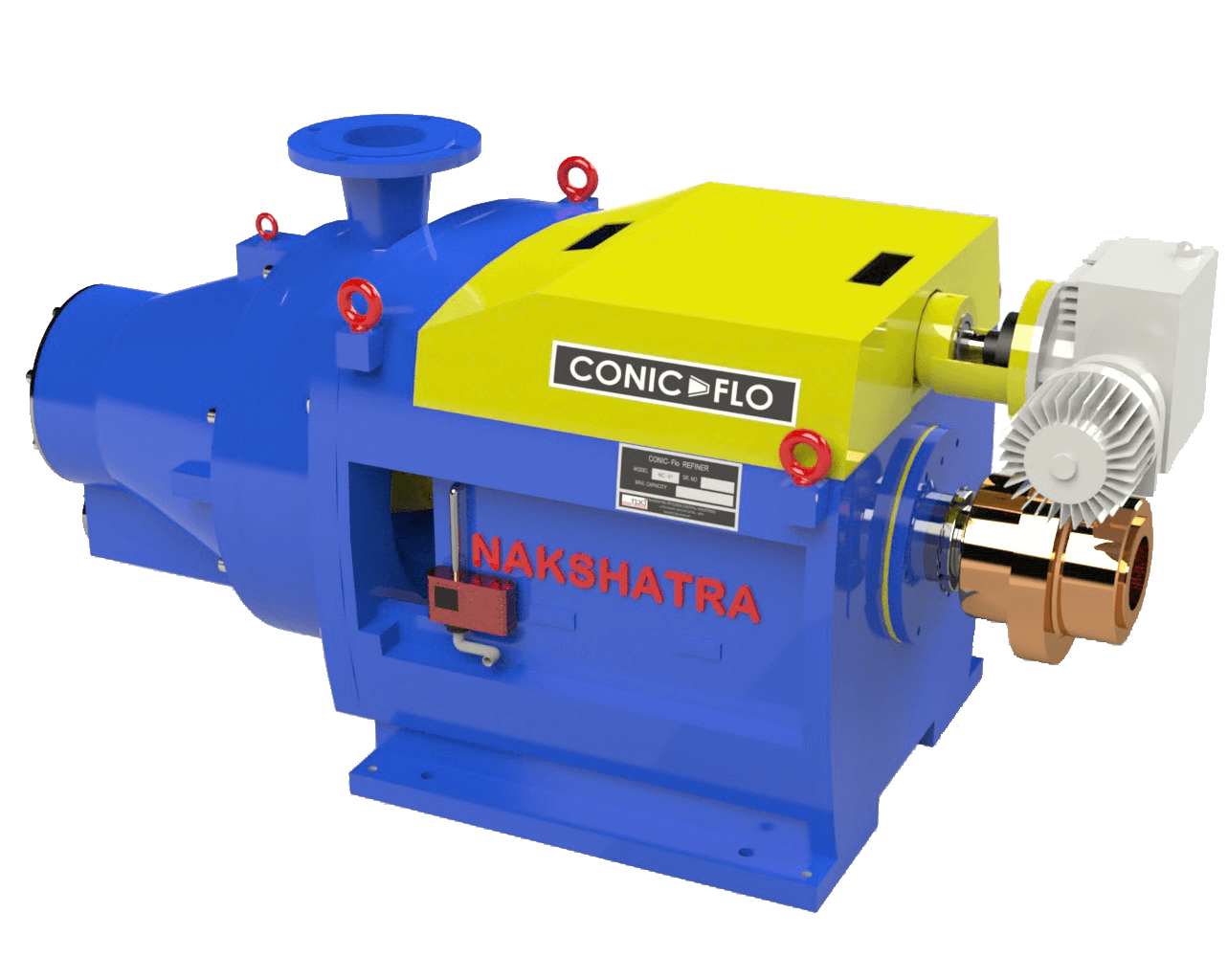

Development of Conical Refiner by nakshatra

Refining is the backbone in the stock preparation stage as well as in paper making. Looking to the high power requirement and also the fast wear of the consumables -fillings (tackles) the process of refining becomes expensive. Each and every mill whether small or large eagerly looks for adaption of any new technology if available

- Uniform low intensity refining with best fiber development at considerable reduction in power.

- Nakshatra conical refiner has 25-30% higher throughput because of its larger inlet.

- Nakshatra Conflo refiner is comparatively stronger, sturdier and robust with bigger shaft diameter, higher size bearings and all other components of standard quality.

- The latest loading And unloading by linear actuator facilitates for controlled gap setting between the rotor and stator.

- Linear actuator comprises of world class Bonfiglioli make gearbox with BLDG motor . The DC motor drive controls the speed to desired POSITION with the help of a potentiometer control panel is provided.

- Electronic torque limiter device is provided which helps to avoid the damage to the tackles by reduction of gap.