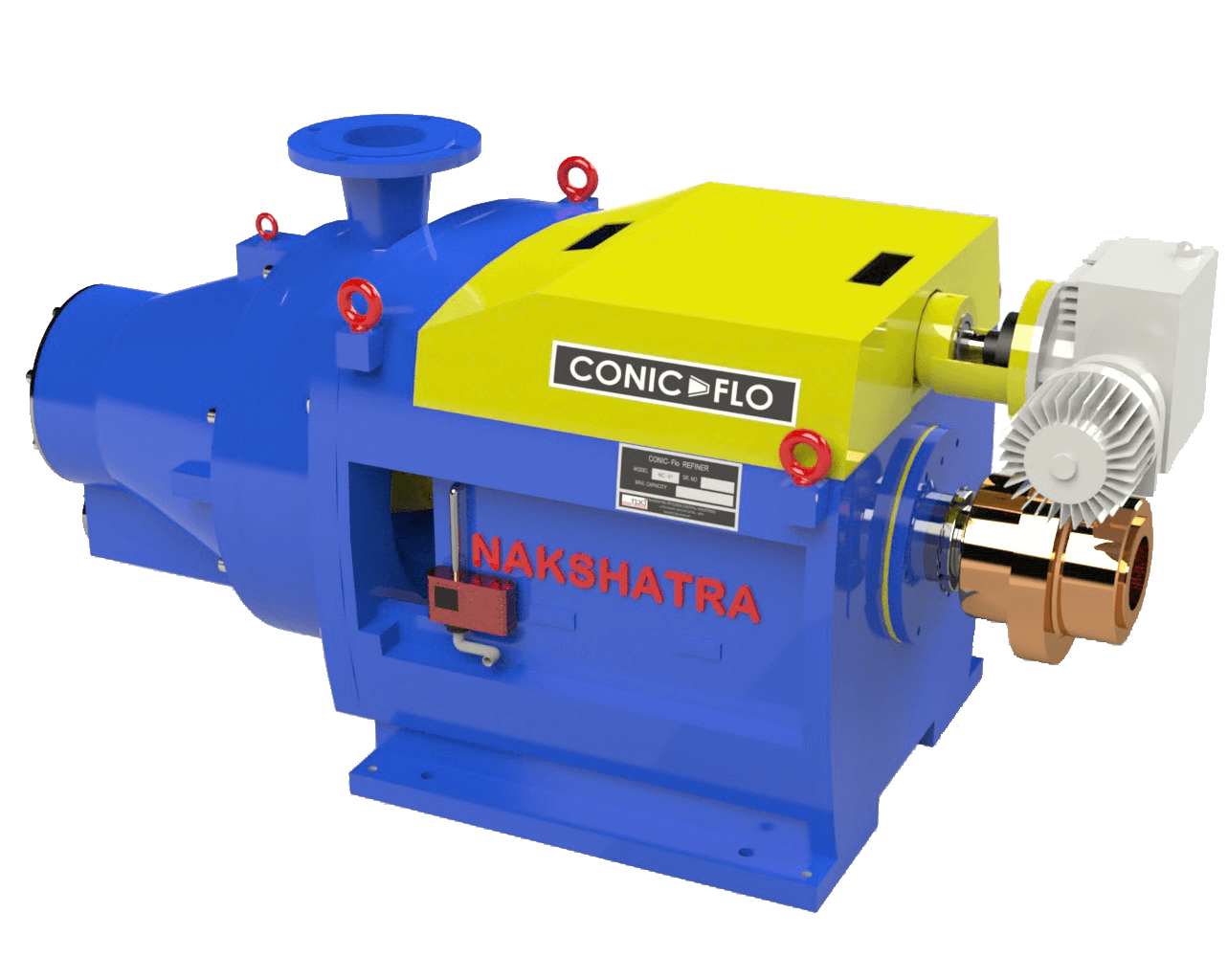

Conical Refiner

Conical Refiner

Significance of Refining

Stock preparation refining may well be considered the most important stage in the paper making process. Not only does it affect the smooth running of paper machine, but the refining stage determine the quality of the paper. Additionally, refining affects the furnish composition and energy consumption which directly influence production costs.

Each paper grade requires development of specific characteristics, which finally can be evaluated on the finished paper product, to ensure the desired results, correct selection of the stock preparation refining system is highly essential.

The most important factors and inter-relationships affecting the refining result.

Fiber Morphology

Bonding ability bonding ability of fibers is the key factor in developing the targeted paper

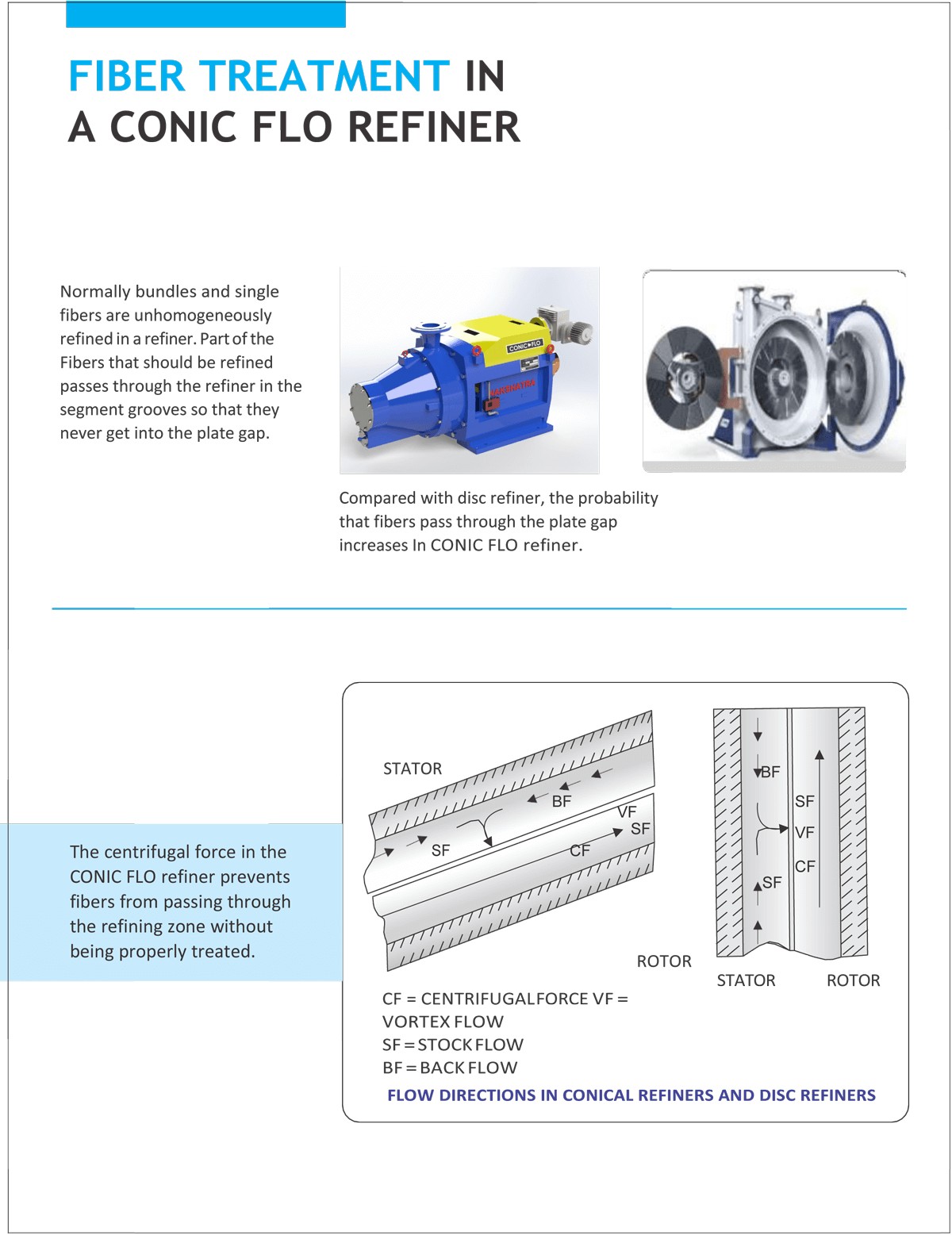

Contribution of Conic flo stock preparation

Refining on paper improve paper quality decrease total costs

Improve

Run-ability and Convertibility stiffness printability

Decrease

Energy consumption raw material component costs

- Smooth fibers

- Poor bonding ability

- fibrillated fibers

- good bonding ability

Conic Flo contribution to total economy

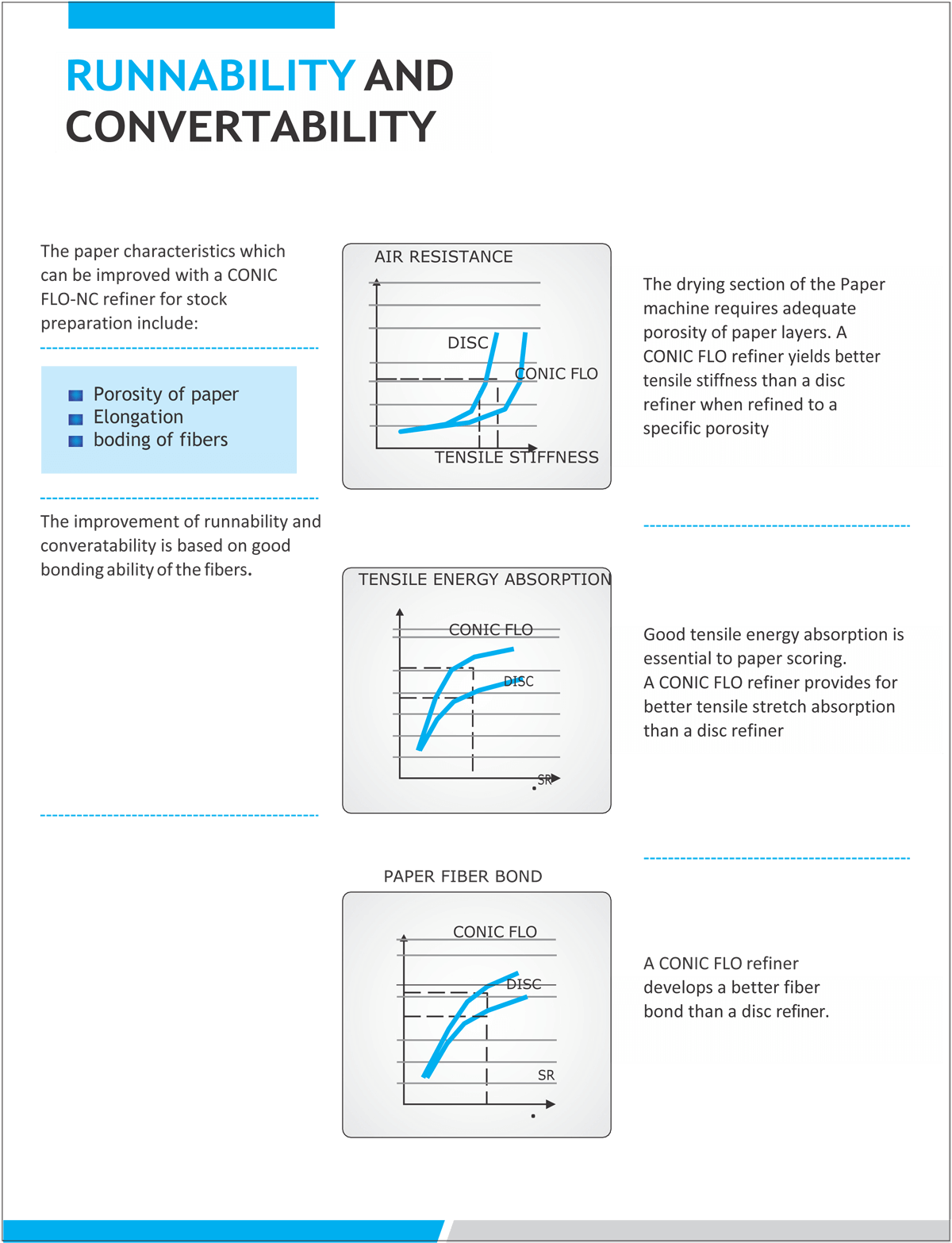

- RUNNABILITY AND CONVERTABILITY

- Improved runnabilty means fewer web breaks and production disturbances both on the paper machine and in the converting process.

- Resistance to scoring

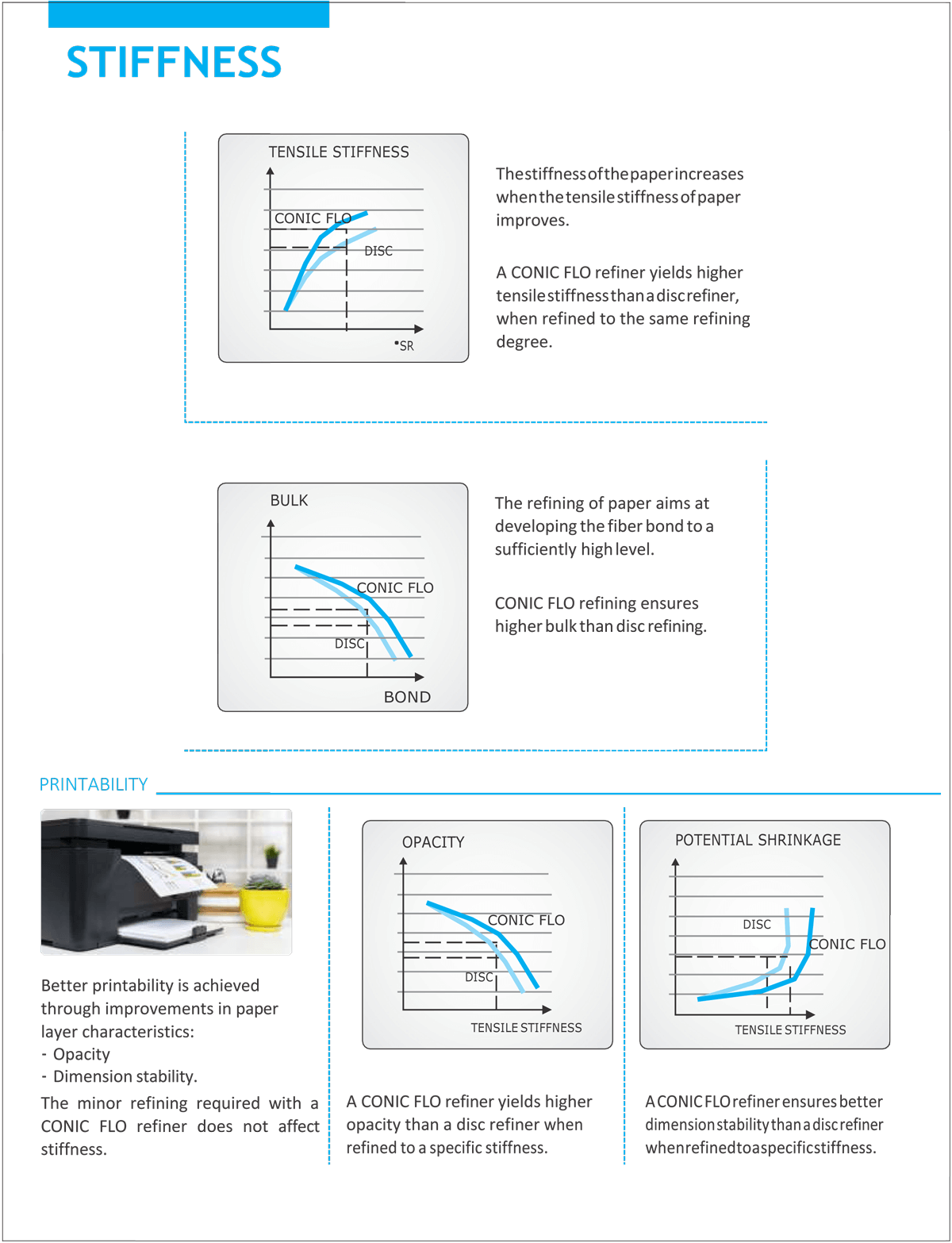

- STIFFNESS

- Better Quality

- PRINTABILITY

- Higher opacity

- Better dimension stability

- Higher bulk

- Better Surface strength

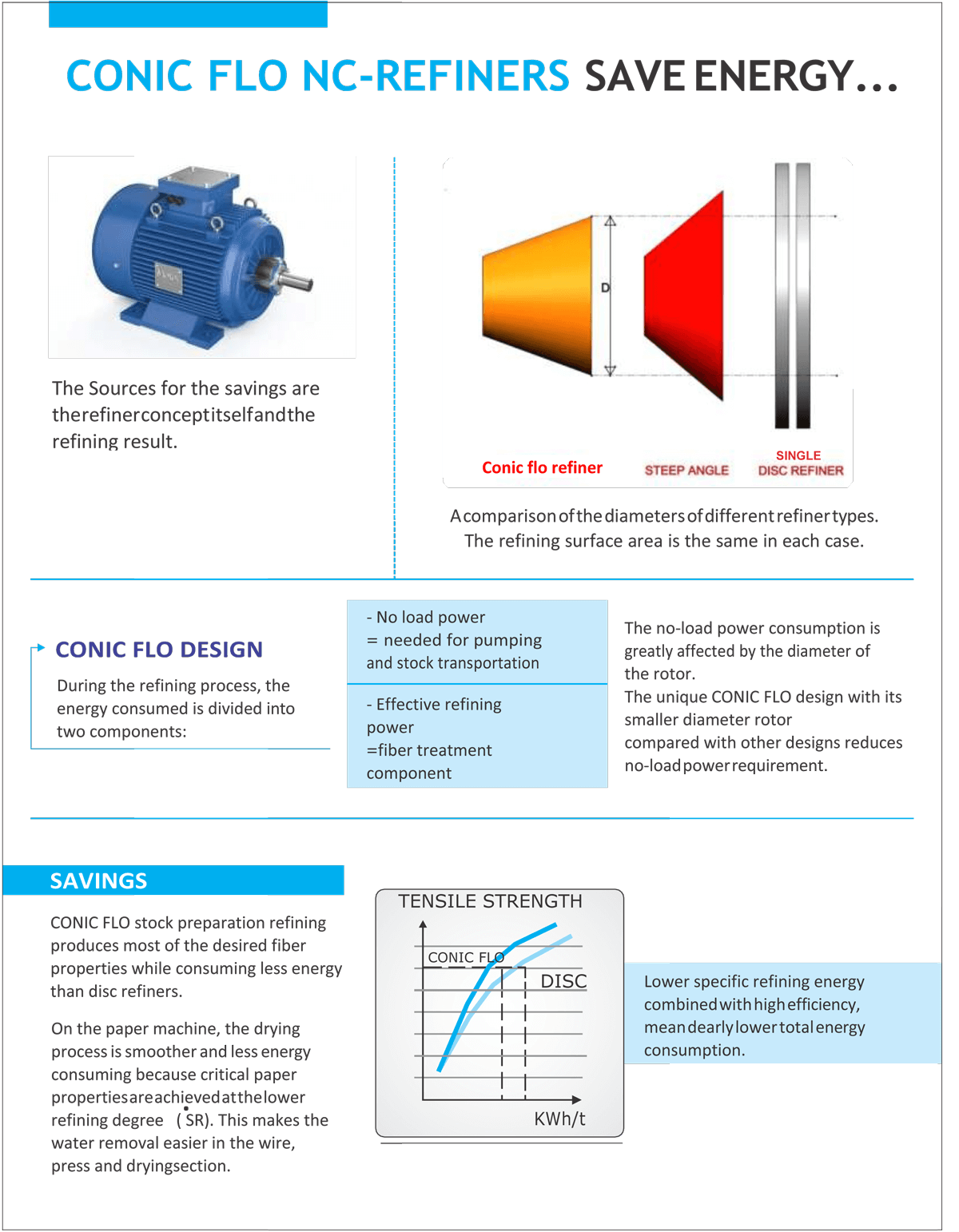

- ENERGY CONSUMPTION

- Decreased refining energy Consumption

- Lower energy need in paper machine drying section

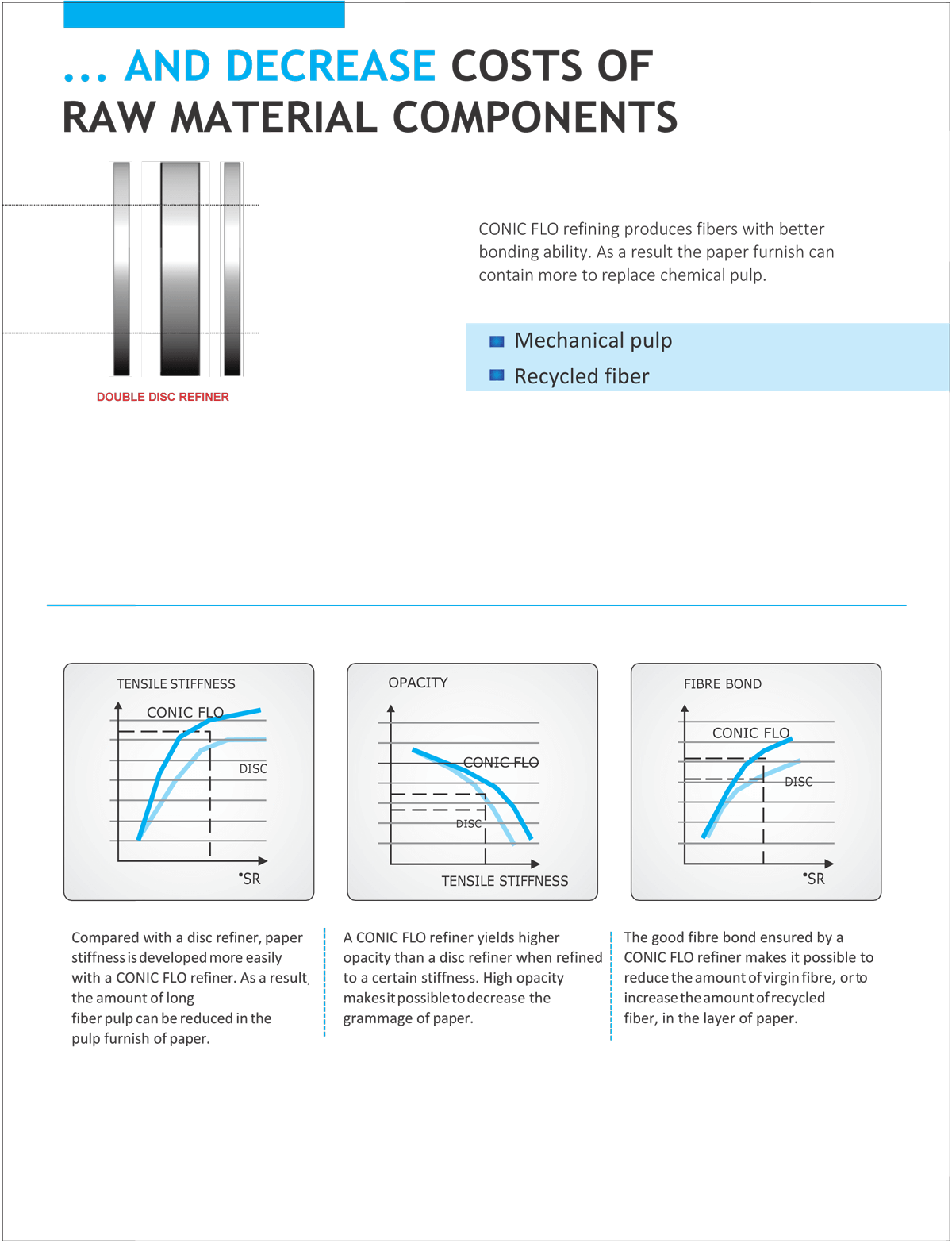

- RAW MATERIAL COSTS

- Savings in amount of long-fiber pulp

- less expensive raw materials

An analysis of the savings potential these factors provide in your process clearly demonstrates the benefits of Nakshatra’s Conic Flo Refiner in total economy approach.

Paper grades are based on several compromises between various factors of which quality properties and production costs are the key elements.

Efficiency, quality and economy are vital issues for paper maker throughout the entire process. CONIC FLO stock preparation refining systems contribute substantially to the operational efficiency of paper mills.

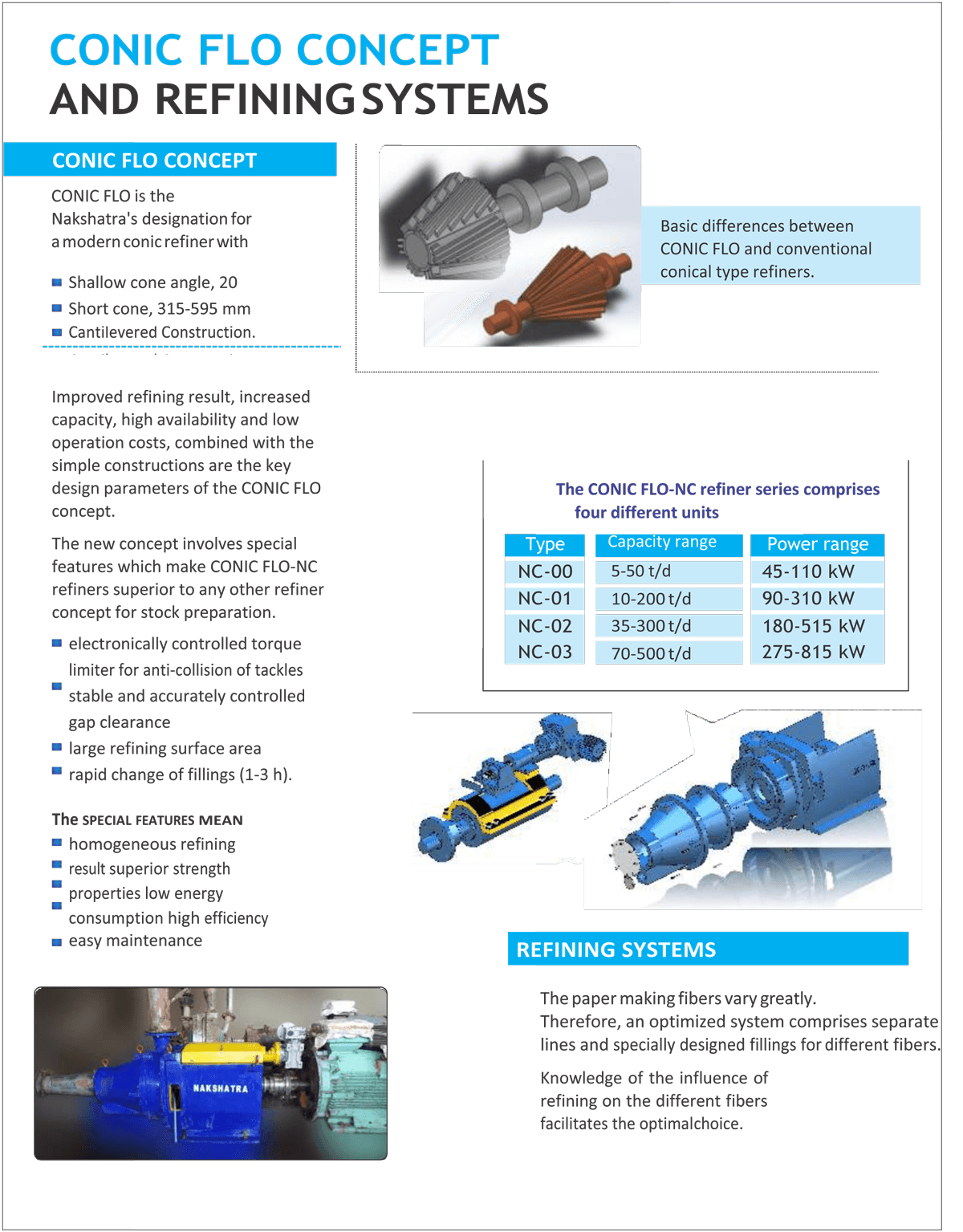

The CONIC FLO-REFINER Series

| Type | Capacity Range | Power Range |

|---|---|---|

| NC-00 | 5-50 t/d | 45-110 Kw |

| NC-01 | 10-200 t/d | 90-310 Kw |

| NC-02 | 35-300 t/d | 180-515 Kw |

| NC-03 | 70-500 t/d | 275-815 Kw |