Theory of Refining

Theory of Refining

Hydraulics

Why are Hydraulic Conditions Important to Refining?

- Rotor is Stable & Centered

- Increases Probability of Fiber Mat Formation

- Fiber Strength Development Potential is Maximized

- Plate Life Potential is Maximized

- Variation is Minimized

It’s just not a good thing to try to refine metal

Negatives to Low Flow

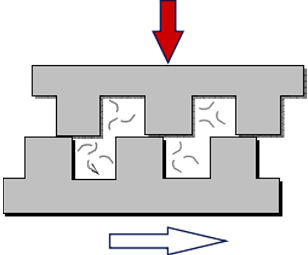

- Little or No Fiber Mat Between Plates

- Fiber Channeling

- High Pressure Rise (25-50 psi)

- Plate Clashing

- Short Plate Life

- Inefficient Refining (power vs fiber development)

- Poor Strength Development

- Increased Fines Generation

Negatives to High Flow

- Inability to Optimize Plate Design For Maximum Strength Development (Compromise)

- Short Plate Life

- Pressure Drop

- Motors Maxed Out

Possible Solutions

Low Flow

- Recirculation

- Parallel to Series

- Pattern Change

- Holdback

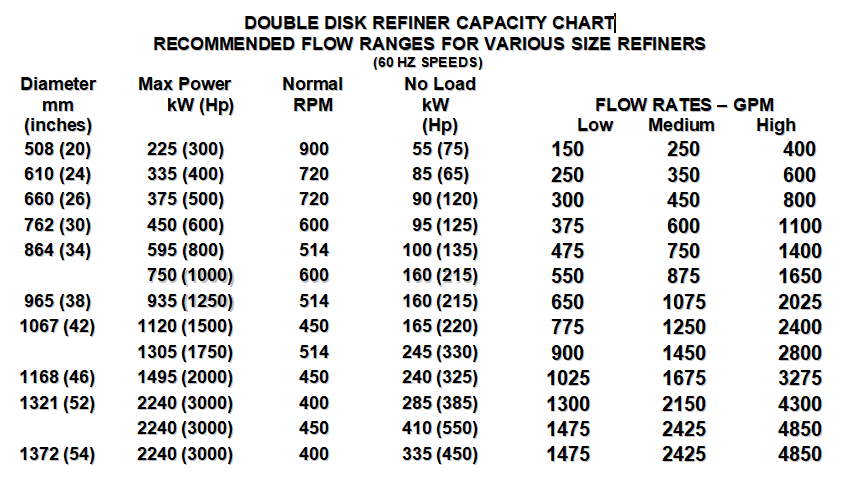

- Smaller Refiner

High Flow

- Pump Change

- Series to Parallel

- Pattern Change

- An Additional &/or Larger Refiner

- Increase Consistency

Consistency

Why is the Proper Consistency Important to Refining?

- Increases the Probability of Fiber Mat Formation

- Fiber Strength Potential Maximized

- Plate Life Potential is Maximized

- Variation is Minimized

Effects of Operating Outside Recommended Consistency

High Consistency

- Plate Plugging

- Poor Fiber Development

Low Consistency

- Little to No Fiber Mat Between Plates

- Inefficient Refining

- Poor Fiber Development

- Fiber Cutting

- Plate Clashing

- Short Plate Life

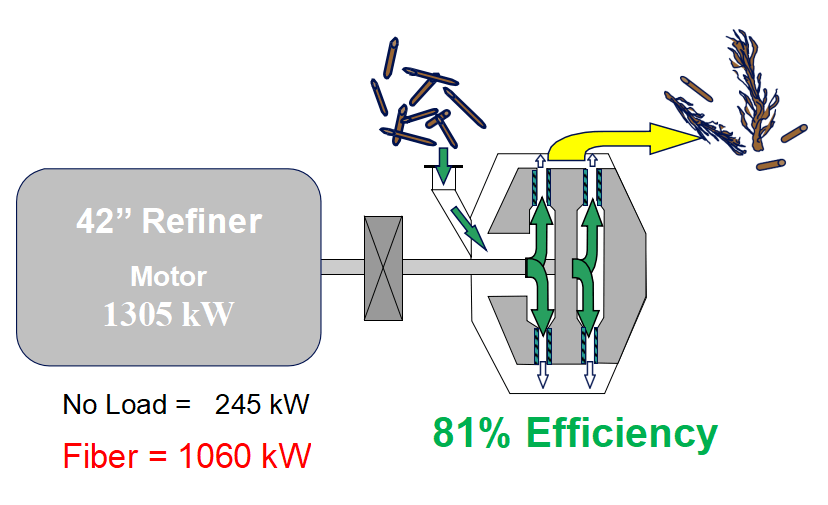

No Load Energy

Definition: The Energy required to spin the rotor in a pulp slurry.

- No Load (kW) = (2.299x10-13)(Diam4.249)(RPM3)

- Dim = Plate diameter in Inches

- RPM = Refiner rotor speed

The Refiner is an inefficient pump

Energy Transfer to Fiber

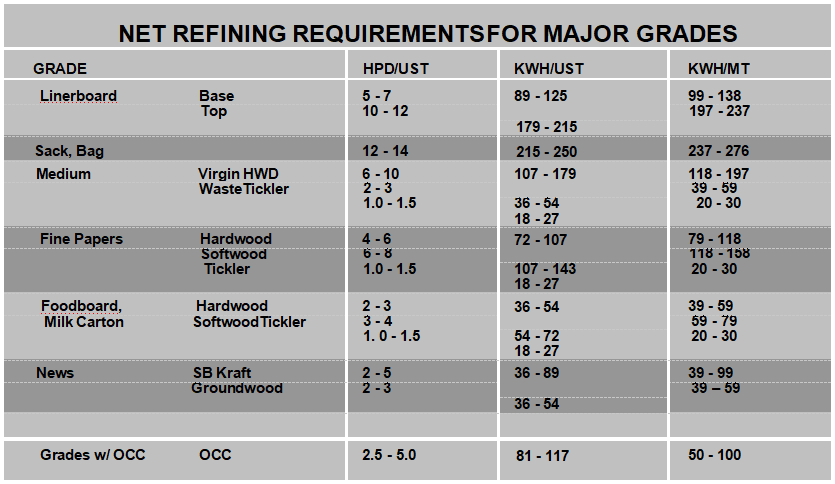

Specific Energy Guidelines